Writing Copy Paper Making Machine Durable Offset Paper Production Line

-

Highlight

a4 paper production line

,a4 size paper making machine

-

ItemWriting Paper Making Machine

-

Poyester Forming Screen Tension7KN/M

-

Felt Tension6KN/M

-

Dry Screen Tension5KN/M

-

Net Paper Width2600mm

-

Raw MaterialWaste Paper

-

Place of OriginHenan, China

-

Brand NamePINGAN

-

CertificationISO9001:20018

-

Model Number2600mm

-

Minimum Order Quantity1set

-

PriceNegotiation

-

Packaging DetailsWooden case

-

Delivery Time6 month

-

Payment TermsT/T, L/C

-

Supply Ability5sets/year

Writing Copy Paper Making Machine Durable Offset Paper Production Line

80T/day writing paper making machine offset paper mill equipment

General description of the writing paper making machine

This writing paper making machine produces writing paper. It is one wire machine and one floor layout. According to request of customer, this writing paper making machine can produce 80T writing paper per day. The final paper dryness reaches 92%.

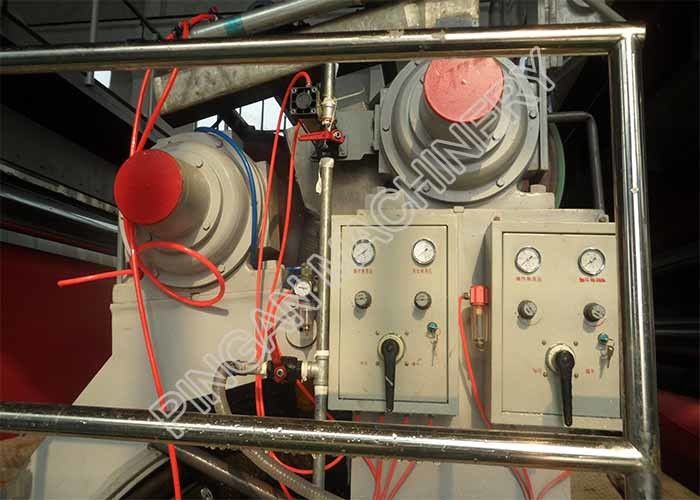

Evner roll description of air cushion headbox

The writing paper making machine adopts air cushion headbox. Here is the general description of the evener roll:

| 1. Double helix row hole , orifice chamfering, throat roll hole open rate 40%, weir roll hole open rate 50%, equip with speed drive device (frequency control). |

| 2. Evener roll rotation speed can be step-less adjusted in range of 1:6. |

| 3. The evener roll's rotate direction can be changed by changing the rotate direction of motor. |

| 4. The gearbox motor and inverter of evener are in the supply scope. |

![]()

FAQ:

1. How to install and maintain the machine?

A: Firstly,we will provide the installation guild with the machine for your reference.

Secondly,our company is responsible for training production workers for you, ensuring that the workers will be independent operation.

2. How can we get the matching accessories or wearing parts conveniently?

A: During the warranty,Our company can replace the accessories for free .Out of warranty,we can provide them at the preferable price .In fact,the wearing parts are standard parts that you could get it in your country at your convenience.

3. Why would I choose your company?

A: Firstly,Our company has rich paper machine design and experience, and is the collection of paper making machinery research, design, manufacture, installation,commissioning and service, becoming one of the multi-functional enterprise.

Secondly,our company could provide the marvelous after-sale services,which is responsible for all installation and debugging, and training the production workers ,ensuring that the workers will be independent operation.

Thirdly,our company persist in the slogan “Customer’s satisfaction is our standing pursuit”.

Warm Tips:

1. Before installation,you should check that equipment’s model and dimension are all right with the parts completed and level remaining.

2. Before the debugging of installation,Checking each part is correct, lubrication supply normal. Water, electricity values reaching the standard.

3. During Operation,you should pay attention to keep daily inspection, cleaning and oiling.and then examine and repair regularly.