Corrugated Paper Small Scale Manufacturing Machines Two Floors High Configuration

-

Highlight

paper roll making machine

,test liner paper making machine

-

ItemCorrugated Paper Making Machine

-

HeadboxAir Cushion Type

-

ColorGrey Or Customized

-

Cooking SystemYes

-

Warranty1 Year

-

OutputFluting Paper And High Strength Fluting Paper

-

Place of OriginHenan, China

-

Brand NamePingAn

-

CertificationISO9001:2008

-

Model Number3700mm

-

Minimum Order Quantity1set

-

PriceNegotiation

-

Packaging Detailswooden case

-

Delivery Time8 month

-

Payment TermsT/T, L/C

-

Supply Ability5sets/year

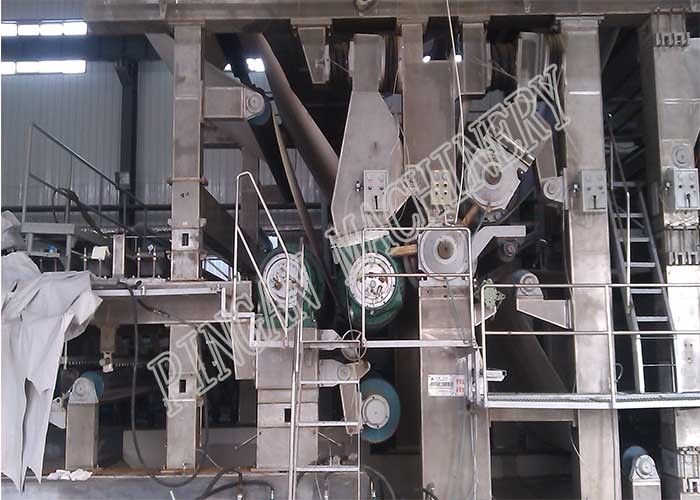

Corrugated Paper Small Scale Manufacturing Machines Two Floors High Configuration

Corrugated paper making machine two floors layout with advanced configuration

Description

This paper making machine is used to produce fluting paper and high strength fluting paper based on the gsm of 90-180g/m2 . This corrugated paper making machine is composed of single wire forming section, press section, dryer section, paper pop reel, base section and auxiliary system etc.

Structure of this corrugated paper making machine

| Forming section | Air cushion type headbox (single wire length 20m) |

| Press section | One vacuum pickup+one vacuum press+on big jumbo roll press |

| Dryer section | 34sets dryer cylinders |

| Reeling section | Horizontal reeling machine |

Main technical parameters

Output: High trenghth fluting paper and fluting paper

Gammage: 90-180g/m2

Net paper width: 3700mm

Reeling width: 3760mm

Headbox lip width: 4100mm

Designed speed: 380m/min

Dynamic balance speed: 450m/min

Working speed: 300-350m/min

Crawl speed: 25m/min

Gauge: 4900mm

Layout: two floors

Main performance requirements and guarantee

This paper making machine can reach the scheduled production capacity150 tons per day at 112gsm (22.5 hours, with size press) . Also take the paper making machine’s inner and exterior performance requirements into consideration at first. This is full set of new paper machine which is well-designed and precision machined.

Paper dryness after each section of the corrugated paper making machine

- Out wire part: ≥22 %

- Out press part: ≥48 %

- Out dryer part: 92%

![]()