Double Wires Kraft Paper Making Machine Air Cushion Headbox Type

-

Highlight

kraft paper manufacturing machine

,kraft paper mill machinery

-

ItemPlant And Machinery

-

Machine StructuctureDouble Wires

-

Headbox TypeAir Cushion Headbox

-

Headbox Quantity2sets

-

Wire Tensioner7KN/M

-

Output PaperKraft Paper

-

Place of OriginHenan, China

-

Brand NamePingAn

-

CertificationISO9001:2008

-

Model Number3600mm

-

Minimum Order Quantity1set

-

PriceNegotiation

-

Packaging Detailswooden case

-

Delivery Time6 month

-

Payment TermsT/T, L/C

-

Supply Ability5sets/year

Double Wires Kraft Paper Making Machine Air Cushion Headbox Type

Plant and machinery kraft paper made in China turnkey project for kraft paper production equipment

Main description

The mentaioned plant and machinery is used to produce super quality kraft paper and fluting paper. Its main structures are:

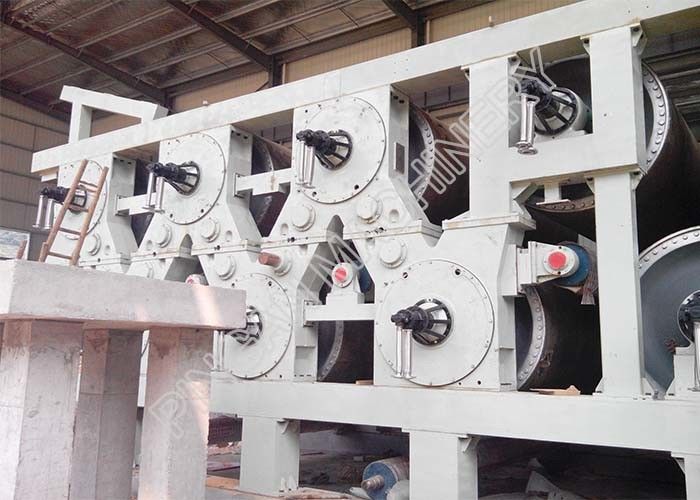

- Double wire forming section

- Big jumbo roll press section

- Dryer cylinder groups section

- Calender

- Reeling machine

- Aulixiary equipment like: MCC, QCS, DCS, rewinder etc.

Wire section wire table frame

Adopts cantilever wire changing mold. The wire table frame of the plant and machinery is composed of breast roll lifting rotary arm, bracket, cushion block and base etc. All cross beams are welded by Q235A steel plate. The cantilever beam is under vacuum couch roll. Its cavity also act as couch roll's drain pipe line. The cantilever side of each cantilever beam in transmission side connects with the base plate's rack by bolts. The T shape groove in the beam is used for fixing dewatering elements. The position of dewatering elements is adjustable according to technological requirements. The contact surface scraping error is not more than 0.05mm, to ensure the flatness and verticality.

Warm Tips:

1. Before installation,you should check that equipment’s model and dimension are all right with the parts completed and level remaining.

2. Before the debugging of installation,Checking each part is correct, lubrication supply normal. Water, electricity values reaching the standard.

3. During Operation,you should pay attention to keep daily inspection, cleaning and oiling.and then examine and repair regularly.

![]()