Hydraulic Headbox Tissue Paper Machine 20T/D Mechanical Drive

-

Highlight

Hydraulic Headbox Tissue Paper Machine

,Hydraulic Tissue Paper Machine 20T/D

,2850mm Trimed Tissue Paper Machine

-

ItemHydraulic Headbox Tissue Paper Making Machine

-

Out PutToilet Tissue Paper

-

Trimed Width2850mm

-

Capacity20T/D

-

Headbox TypeHydraulic

-

Headbox BrandWeiya

-

Basic Weight16gsm

-

Place of OriginHenan, China

-

Brand NamePingAn

-

CertificationISO9001:2008

-

Model Number2850mm

-

Minimum Order Quantity1set

-

Packaging Detailswooden case

-

Delivery Time3 month

-

Payment TermsT/T, L/C

-

Supply Ability10sets/year

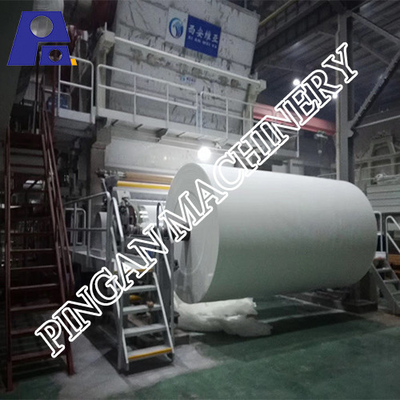

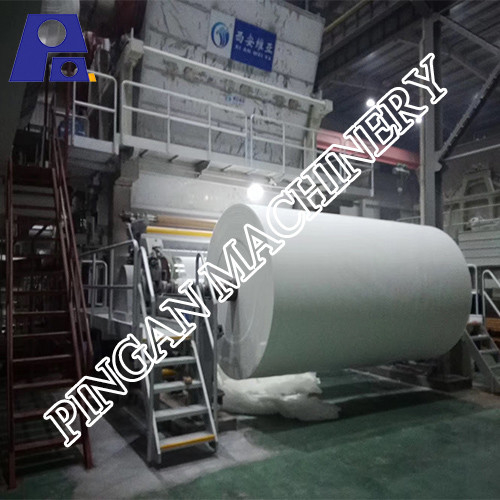

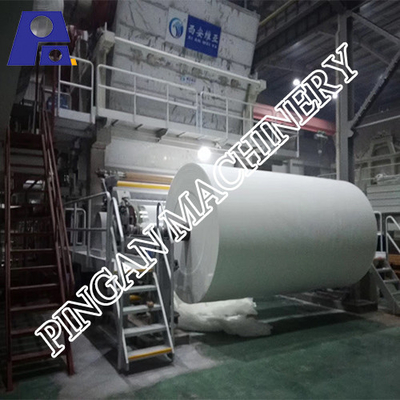

Hydraulic Headbox Tissue Paper Machine 20T/D Mechanical Drive

Hydraulic headbox tissue paper making machine

Description

This tissue paper machine consist of hydraulic head box, Fourdrinier wire, Yankee touch press, Yankee dryer, dryer hood, mechanical/electric drive, air control system, sole plate, pope reel etc.

To ensure output paper quality and capacity, this machine adopts hydraulic headbox. Headbox lip width 3150mm. Headbox pulp consistency is 0.1-0.5%. Suitable pulp temterature is 20-30°C. Headbox lip opening range is 0-70mm and horizontal adjust range is 0-25mm. The design reflux is 10%.

Main function of headbox: Headbox is to evenly distribute the pulp in the transverse direction of the whole paper machine, and reduce the fiber flocculation as far as possible, so as to produce uniform and quantitative paper.

Headbox main structure:

| No. | Item | Description |

| 1 | Main pulp inlet pipe |

According to the theory of fluid mechanics, the distributor with equal pressure and velocity is designed and manufactured. The conical and parabolic designs ensure the uniform distribution of pulp in the paper machine. |

| 2 | Pulp distribution orifice |

It is used to guide the slurry of the square cone main pipe into the headbox transversely, which plays the role of uniform slurry distribution. |

|

3 |

Dilution orifice |

The specially designed dilution orifice (zone width is about 70mm) ensures that the slurry is fully mixed with the diluted white water. |

| 4 | Throttle plate |

When the pulp with dilution water enters the throttle plate, strong turbulent mixing occurs, which makes the slurry water fully mixed. |

| 5 | Transition room |

The pulp flows through the balance chamber of the high turbulence headbox to ensure the ideal micro turbulence and balance the possible non-uniformity of the pulp in the transverse direction of the paper machine. |

| 6 | Turbulence generator |

Through the high turbulence generator, the pulp flow can ensure the ideal micro turbulence, fully disperse the fibers in the pulp, prevent the occurrence of fiber flocculation, and ensure the paper has good uniformity. |

| 7 |

Upper and bottom lip plate |

Flow channel before pulp approaching. |

Company information

Qinyang Pingan Light Industry Machinery Co., Ltd is a large scale enterprise. Specialized in paper making machinery, covering the sentific research, design, manufacturing and installation.

Since the reform and opening up policy of our state, we have exported our machines and equipment to many countries like Indonesia, UZ,Russia, Kirgizstan, KZ, Turkmenisan, Suriname , Syria, Magolia, Mali, Uganda, Mexico and Nigeria etc.

Installation and commissioning

| 1. | The supplier is responsible for guiding the installation (the buyer is responsible for the expenses of the supplier's installation and commissioning personnel) |

| 2. | The supplier shall send one engineer to guide the installation and comissioning on site. |

| 3. | The buyer shall be responsible for the hoisting of the equipment required in the installation process. |

| 4. | The buyer shall be responsible for the tools (except special tools) required in the installation process. |

| 5. | The consumables (such as electric and gas welding apparatus, welding rod, welding wire, raw tape, etc.) required in the installation process shall be provided by the buyer. |

| 6. | During commissioning, the buyer shall send personnel to actively assist the supplier. |

![]()