-

Highlight

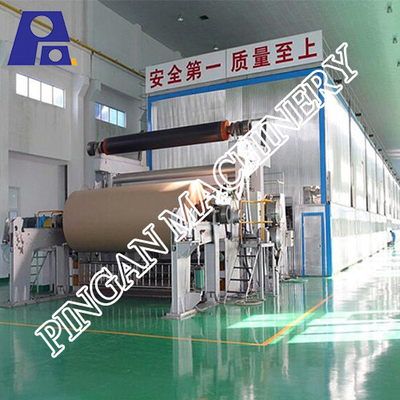

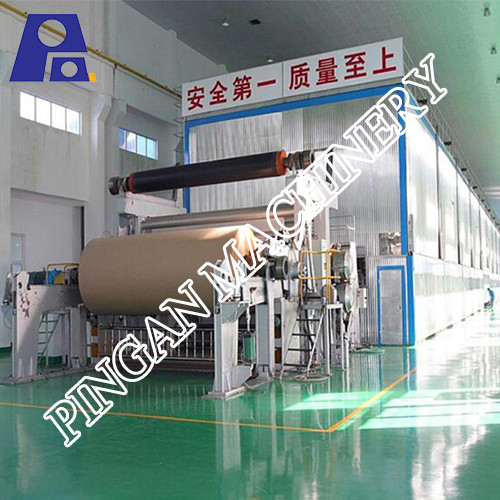

Headbox Type Fluting Paper Machine

,Air Cushion Fluting Paper Machine

,2ply Wire Fluting Paper Machine

-

Forming Section2ply Wire

-

OutputKraft Paper, Fluting Paper, Testliner Paper

-

Headbox TypeAir Cushion Type

-

Delivery8month

-

Headbox BrandXi'an Weiya

-

Item3200 2ply Wire Paper Making Machine

-

Place of OriginChina

-

Brand NamePingAn

-

CertificationISO9001:2008

-

Model Number3200mm

-

Minimum Order Quantity1set

-

PriceNegotiation

-

Packaging Detailswooden case

-

Delivery Time3month

-

Payment TermsL/C, T/T

-

Supply Ability10sets/year

Air Cushion Headbox Type Fluting Paper Machine 2ply Wire Forming

Description

This 3200 fluting paper making machine is high configural machine with reasonable design, which when design we put paper quality, capaicty, energy saving, reduce operation cost at the first consideration.

To ensure paper quality and capacity, we use air cushion type headbox in this paper making machine. Headbox lip width: 3500mm. Its basis configurations are square cone tube, ladder tube bundle pulp separator, double homogenizing roll rectification, and lip pulp approaching device with vertical lip edge.

Headbox body includes side wall, back wall, front wall, base and top cover. It 's welded by 304 and Q235, eliminating weld stress, machining, polishing and grinding. Frame material is HT200. Also it is convenient to install.

Air cushion headbox structure

| Pulp distribution device |

Pulp distribution device consists of square cone tube and ladder diffusing holed board. |

|

The square cone tube consists of inlet flange (couple), round square pipe, square cone tube, square round pipe, outlet flange (couple). The ladder diffusing hole is third reaming. Material is organic glass. |

|

|

The square cone tube can be disassembled. It is convenient to clean after overturn. |

|

| Evener device |

Evener device is double rolls structure- throat roll and lip roll. Drill double helix hole. The holes open rate is 35% and 52%. Material is 304. |

|

Rectifier roll transmission is geared reducer AC frequency conversion motor. Both positive and negative running are okay, frequency controls between 9-50r/min |

|

| Lip device |

Lip device consists of top lip, bottom lip and the top lip opening total adjusting device, lip opening fine turning device and lip opening indicator. |

|

Top lip outlet has upright slice which is used for fine turning of lip opening. It is convenient to disassemble. Material is stainless steel. |

|

|

Top lip opening’s total adjusting device consists of worm gear, top lip plate hinge shaft device, bracket, drive shaft and hand wheel etc. According to working speed and paper weight of paper making machine, it need to adjust the size of lip opening. It takes the upper lip cardinal axis as axle center and driving the worm and worm gear box device through hand wheel. There is lip opening indicator in operating side to show the height of lip opening. |

|

|

Top lip opening fine turning device consists of mini-worm gear, connecting shaft, hand wheel, dial indicator and protective cover etc. It is used to make fine turning of top lip plate to ensure paper deviation of basis weight in cross direction. |

|

|

Sprayer |

It's at top inside of the box. it can eliminate froth in pulp slurry and wash inner box surface. |

1ply wire paper making machine headbox material description

|

Top lip plate: Material is stainless steel 316L |

| Bottom lip plate: Material is stainless steel 316L |

|

Side wall: Material is stainless steel 304 |

|

Back wall: Material is stainless steel 304 |

| Front wall: Material is stainless steel 304 |

| Base: Material is stainless steel 304 |

| Tope cover: Material is stainless steel 304 |

|

Cone tube: Material is stainless steel 304 |

![]()