-

Highlight

Recycling Kraft Paper Manufacturing Machine

,OCC Kraft Paper Manufacturing Machine

,Kraft Paper Manufacturing Machine 100T/D

-

Raw MaterialOCC

-

OutputFluting Paper, Kraft Paper

-

Capacity100T/D

-

Paper Basic Weight100-210gsm

-

Headbox BrandXi'an Weiya

-

Item3200 2ply Wire Paper Making Machinery

-

Place of OriginChina

-

Brand NamePingAn

-

CertificationISO9001:2008

-

Model Number3200mm

-

Minimum Order Quantity1set

-

PriceNegotiation

-

Packaging Detailswooden case

-

Delivery Time8month

-

Payment TermsL/C, T/T

-

Supply Ability10sets/year

OCC Recycling Kraft Paper Manufacturing Machine 100T/D

Description

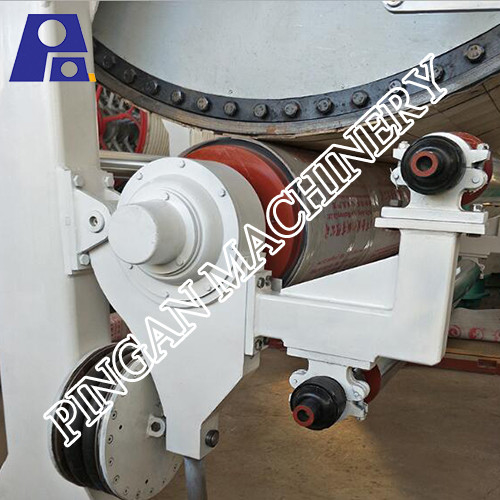

This OCC recycling paper making machinery consists of wire section, press section, dryer section, size press, pope reel, rewinder etc. Wire section of this machine includes following items:

| 1 | 2sets air cushion headbox |

| 2 | white water pan |

| 3 | forming plate |

| 4 | dewatering plate |

| 5 | wet suction box |

| 6 | high and low suction box |

| 7 | breast roll |

| 8 | vacuum couch roll |

| 9 | wire driving roll |

| 10 | wire leading roll etc. |

The fourdrinier is polyester forming wire and cantilever type wire-changing device. The jack on the operation side. Wire design tension: 7KN/m. Elongation is 1.5%.

Forming section rolls in this paper making machine

| 1 | Breast roll and bearing | 2sets |

| 2 | Guide rolls | 8sets |

| 3 | First wire drive roll | 1set |

| 4 | Wire drive roll | 1set |

| 5 | Compound roll | 1set |

| 6 | Vacuum couch roll | 1set |

Compound roll description

Roll body is stainless steel. Roll surface there is double spiral arrangement blind hole, equip with rolling bearing and bearing seat. Both ends of the roll adopts iron casting heat set.

Spindle nose: Material is 45# steel. 1:12 taper thermal refining.

Bearing: 113536

Lubrication: Grease lubrication

![]()